![]()

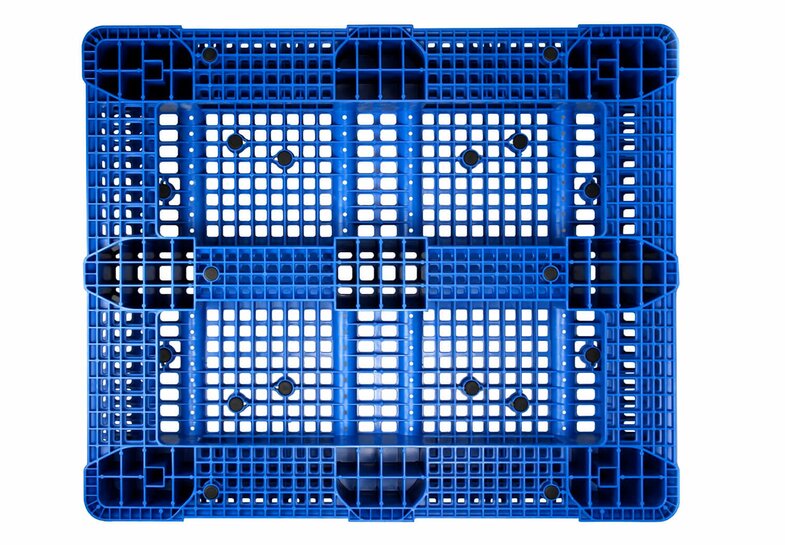

PRODUCTION LINES

The pallets are suitable for use on chain and roller conveyors without restrictions. Rubber inserts in the bottom reduce wear and thanks to the wide skids the load remains stable.

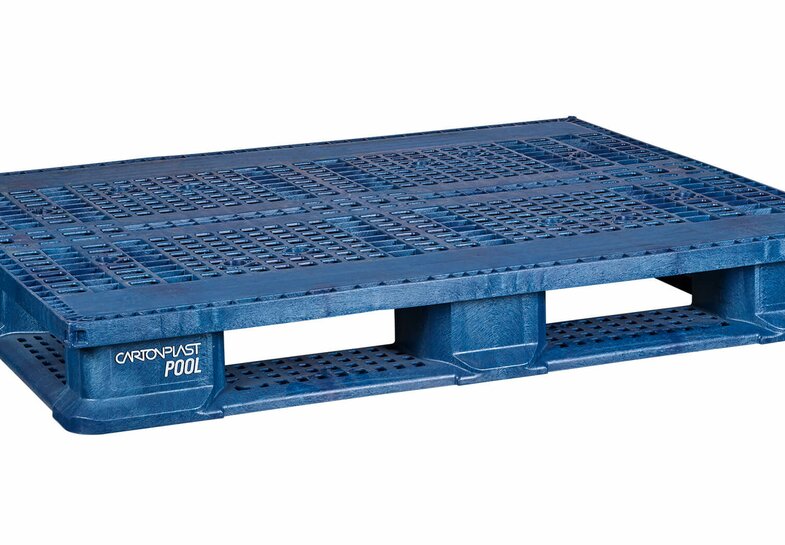

![]()

SHRINK LINES

The bottom and the spacing of the runners correspond to those of conventional wooden pallets, so that you can use them on lifting platforms and lifting tables of automatic shrink lines, without the need to adjust the control system for this purpose.

![]()

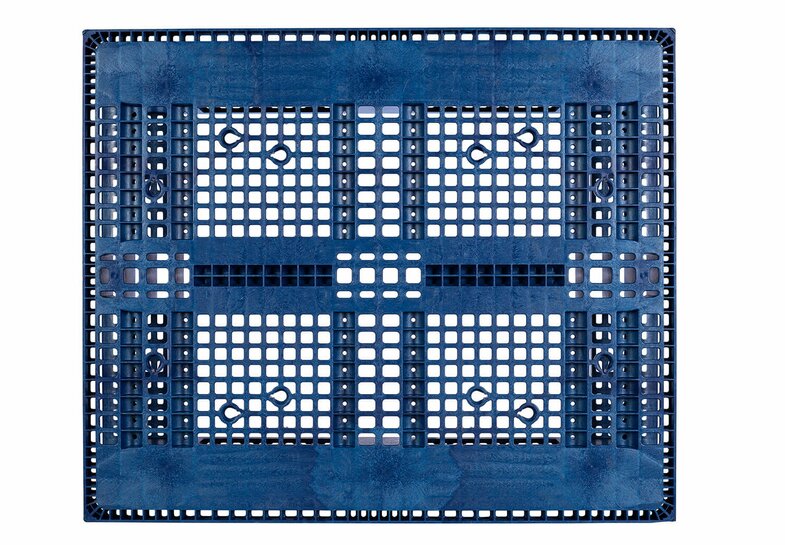

HANDLING

The beveled edges make it easier for the forklift operator to pick up the pallet without damaging the goods or the pallet. Rubber inserts on the bottom increase the friction of the pallet on the forklift tines to prevent the load from slipping when starting and braking.

![]()

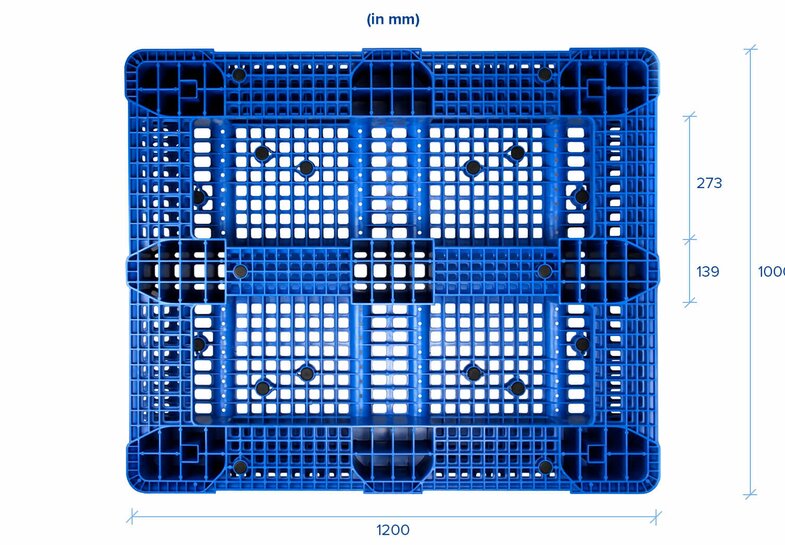

STABILITY

Integrated into the top of the Cartonplast plastic pallet are six U-shaped crossbars running across the entire width, which provide stability. In the model with five runners, two further connections between the longitudinal runners on the underside provide additional stability.

![]()

HYGIENIC CLEANING

Plastic pallets basically have the better hygienic properties because they are non-absorbent. They are cleaned with high tech industrial sanitation technologies at Cartonplast, so food and beverages stay safe during transportation and even trucks stay cleaner.

![]()

COST REDUCTION

Using recyclable plastic pallets reduces costs in many ways: Lower transportation costs through less weight, savings through less damaged products or equipment and decrease warehouse management costs when working with a pooling partner such as Cartonplast.